Top 10 Tips To Assess PAT Compliance in Sutton Coldfield

The UK's regulatory environment for Portable Appliance Testing differs fundamentally from the requirements that govern fixed electrical installations or equipment used to protect against fire. PAT testing, unlike fire extinguisher service, is governed by an broader health-and-safety framework that places more emphasis on risk assessment and duty to care than on mandatory testing schedules. Electricity at Work Regulations, 1989, are the core legal requirement. They state that all electrical equipment (including portable devices) must be maintained in order to avoid danger. The Regulations, however, do not stipulate how this maintenance must be performed, or mandate a particular testing frequency or methodology. It is the responsibility of the dutyholder, usually the employer, to carry out a sufficient and suitable risk assessment in order to determine the appropriate maintenance and inspection program. Compliance is therefore not only demonstrated by test certificates, but also by a process of risk-based decisions, competent implementation and thorough documentation which proves an organized approach to electrical safety at the workplace.

1. Electricity at Work Regulations, 1989: The Legal Basis

Regulation 4(2) is the cornerstone of compliance for PAT testing. This states: As may be required to prevent harm, all systems are to be maintained so that they can be prevented, as far it is reasonable practicable. The duty to maintain electrical equipment is a legal obligation for employers and other dutyholders. The term system includes portable appliances. In addition, the regulations are not specific about "PAT" testing; rather, they refer to "maintenance," meaning a more general concept, which encompasses visual checks, user tests, and combined testing and inspection. The frequency and type of maintenance required are determined by the risk assessment, not by a fixed legal timetable.

2. Act 1974: The role of Health and Safety at Work Act 1974

The Health and Safety at Work Act 1974 is the main legislation that establishes employers' general duties towards employees and others. The Act of 1974, which is the most important piece of legislation, outlines the duties that employers have toward employees and others. In section 2 of the Act, employers are required to provide, as far as it is reasonable, for the health, safety, and welfare of their employees. This includes providing safe plant and systems of work, which encompasses electrical equipment. Section 3 extends their duty to other people, like visitors, contractors, or members of the general public. The PAT process is the best way to fulfil these duties because it is structured and provides a method for ensuring safety of electrical equipment.

3. Code of Practice of IET on In-Service Inspection, Testing and Inspection of Electrical Equipment

Although not law, the Institution of Engineering and Technology Code of Practice (IET Code of Practice) is universally recognized as the benchmark of best practice for PAT tests. It contains detailed information on how you can implement a compliance maintenance regime.

Definitions and classifications of appliances.

Details procedures for formal inspections of the product and inspections with testing.

The equipment type, operating environment and recommended inspection and test frequencies will determine the initial frequency.

Pass/fail criteria for test results.

Courts and Health and Safety Executive inspectors (HSE), will use this code to judge if a dutyholder’s maintenance regime is “suitable and adequate.” Departures from the code which are not supported by robust and documented reasons can be interpreted to be non-compliance.

4. Risk Assessment Is Priority No. 1

HSE advocates an approach based on risk for PAT testing. This is a departure from the outdated idea of annual blanket testing. Dutyholders are required to conduct a thorough risk assessment in order to determine whether inspection and testing is necessary, what type of inspection and test should be conducted, and how often. This assessment is influenced by:

Equipment type: A double-insulated (Class II) appliance in a low-risk environment may only need a visual check, while a Class I appliance in a workshop may need regular formal testing.

Construction sites, workshops, and warehouses present a high level of risk. Offices and hotels are generally lower risk.

Users: Are the equipment users members of staff or public?

The appliance's history: Has it been damaged or is it new?

A compliant system is defined by this risk assessment, not by the volume of tests conducted.

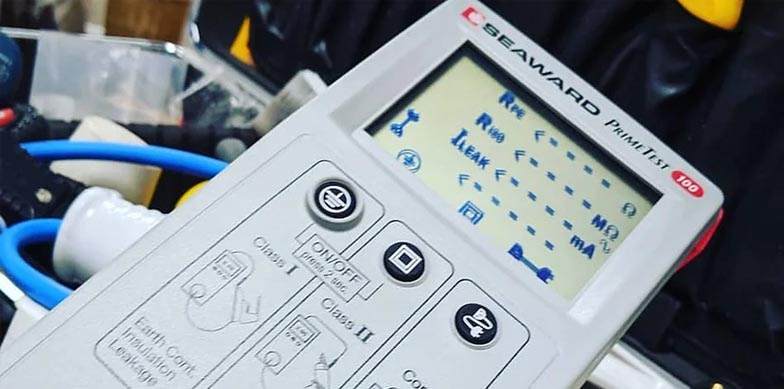

5. The Concept of "Competence" for Testers

Regulation 16 of 1989's Electricity at Work Regulations requires that those who work with electrical systems have the technical knowledge and expertise to prevent danger. The "competence" required for PAT testing does not require formal qualifications, but the tester should have:

Knowledge of electricity is essential.

Understanding and practical experience of the system on which they are working.

Understanding of the hazards and precautions required.

Ability to correctly use the test equipment and interpret the results.

City & Guilds qualification 2377, while popular and providing excellent training, can also be used to demonstrate competence. The dutyholder has to be able demonstrate that the individual conducting the test is competent.

6. Documentation and Record-Keeping Requirements

The Electricity at Work Regulations does not require that records be kept. According to Regulation 29, it is possible to defend yourself by proving that you have taken all reasonable measures and exercised due diligence to avoid committing a crime. Primary evidence of due care is comprehensive records. A compliant record-keeping system should include:

An asset register of equipment.

Documentation of the risk analysis and the maintenance plan.

Reports detailing each formal inspection or test. Includes appliance description, test result, pass/fail, next test date, and tester identity.

HSE or the local authorities can easily access these records.

7. Labelling and Identification of Appliances

Labelling is an important part of a PAT system that's compliant. Labelling should include the following information for each appliance that has passed a combined formal inspection and test.

A unique asset ID number that ties it to the record.

The date the test was conducted.

The date for the next test (or re-inspection).

The name or identifier used to identify the tester.

The label provides a clear visual indicator of an appliance's compliance status for users and inspectors. Labels are durable, non-metallic and non-conductive.

8. The HSE Enforcement stance, and "Myth-busting"

The HSE has worked actively to clear up misconceptions regarding PAT testing. They emphasize that:

The annual testing of all equipment is not a legal requirement.

There is no requirement for businesses to hire a third party contractor if they are able to test themselves.

Visual inspection can often be more effective than electronic testing in identifying the majority of faults.

A law enforcement officer will be looking for a risk based approach. An enforcement officer may view a company less favorably if it tests all equipment blindly every year, without supporting risk assessments.

9. Interplay with Other Laws: PUWER

The Provision and Use of Work Equipment Regulations 1998 (PUWER) also applies to portable appliances. PUWER stipulates that equipment must be fit for its intended purpose, in a safe condition, and inspected regularly to ensure safety. Regulation 6 requires inspections when safety depends on installation conditions. PAT tests are a crucial method to meet PUWER's requirements for inspections and maintenance of electrical work equipment.

10. Due Diligence in Insurance

While the law relies on a risk assessment, insurers may have requirements that are specific. As a condition to coverage, an insurance policy could stipulate that PATs are conducted by a third party annually. If this condition is not met, it could invalidate any claim. Insurance companies and HSE will also scrutinize the dutyholder’s risk assessment and PAT testing records in the event that an electrical incident occurs. A well-documented, risk-based system is the strongest possible evidence of due diligence and a robust defence against prosecution or a invalidated insurance claim. Follow the top rated Sutton Coldfield PAT testing for more info.

Top 10 Tips To Speed Up Response Time To The Fire Extinguisher Service in Sutton Coldfield

In the context for compliance with fire safety responding times to emergencies are not merely a matter of convenience but are an essential element to maintain continuous legal compliance and operational safety. The Regulatory Restructuring (Fire Safety) Order (2005) stipulates that the equipment used for fighting fires maintain a high degree of efficiency. Damaged, missing or destroyed equipment is an infraction to the order. Your risk exposure, security and continuity of operations are directly affected by a provider's response time to both emergency and scheduled demands. Slow responses can leave premises unprotected, disrupt business operations during audits, and reveal inadequate due diligence. To assess a service's capacity to respond to emergencies, from routine scheduling to emergencies, it is crucial to know the various service levels, geographical restrictions, contractual guarantees and the operational capability that allows swift and effective actions.

1. Timelines for scheduled service appointments in Sutton Coldfield

The efficiency of a provider's scheduling system for regular annual services is the primary indicator of their operational competence. A company that is well organized will contact you approximately 4-6 months before the expiration date of the certificate to schedule your next appointment. The company should be flexible with scheduling and offer specific timeslots for AM and PM or a confirmed day for the engineer to come. Excessively long lead times (e.g. the requirement to book 3+ months ahead) or inability to offer a definitive date can indicate understaffing, poor resource management, or excessive extension, which could lead to a lapse in your certification coverage.

2. The Emergency Call Out Response Definitions, Tiers, and levels

All reactive calls aren't all created in the same way. Trustworthy providers offer a clearly defined hierarchy of emergency responses, each with its own time-limit. An ordinary urgent call (e.g. a defective or missing fire extinguisher) might be a target for a response time of 24 hours. In a high-priority emergency (e.g. or several units being discharged following small incidents or a significant flaw discovered during an audit) should trigger a more rapid response, often within a few working hours or next-day attendance. To manage expectations in the contract or service agreement should clearly define these categories along with their intended time for response.

3. Geographical coverage of local engineers and their availability in Sutton Coldfield

Response times are intrinsically tied to the Sutton Coldfield. A large company may have a global brand presence but relies on a network of regional engineers. It is important to determine whether the engineers are situated within your local area or if they travel from some distance. This will affect the emergency response and scheduled times. If a company has a dense network local engineers, they can respond quicker and with lower costs. Always ask "Where is the nearest engineer near the postcode we have?"

4. Guaranteed Response Times in Service Level Agreements (SLAs) in Sutton Coldfield

The primary thing to be considered is whether your Service Level Agreement guarantees response times. An unsubstantiated "attend promptly" promise is of no use. A strong SLA should contain measurable Key Performance Indicators. These contractual guarantees provide you with recourse in case the provider consistently fails to perform their duties.

5. Communication Protocols and Dedicated Assistance Lines in Sutton Coldfield

The efficiency of communication is crucial to speed up service. It is essential to know the process of responding to requests for service. Does the company has a dedicated helpline to customer service or a specific email address to deal with urgent requests? Are they available during normal business hours and after hours? The top providers offer an instant phone number to a coordinator who will send an engineer right away, without being stuck in a crowded waiting list. This is crucial in an emergency.

6. Support for weekends and out-of-hours in Sutton Coldfield

Fire incidents and malfunctions do not observe 9-5 hours of work. For environments with high risk (e.g. data centres, 24/7 manufacturing and care homes) or in the event of an out-of-hours incident, being able to reach support is essential. It is important to determine if the provider has a real 24/7 emergency service or only operates during business hours. If they do offer after-hours support, inquire about the cost of premium services and the response time guaranteed in these cases. They could be vastly different than the SLA for daytime support.

7. Fault Resolution vs. Initial Attendance Time

There must be a distinction between the initial reaction time (an engineering team arriving on site to assess an problem) versus the time frame for resolution of fault (the time when the equipment was completely repaired, replaced or conforming). A provider could respond quickly to condemn the extinguisher as defective, but take a few days to put it in place and find a replacement. Your SLA should cover both measures. A provider should strive to resolve common problems such as a missing extinguisher in the first visit.

8. Impact of Response Delays on Compliance and Insurance in Sutton Coldfield

The implications of a slow response is crucial. If you fail to replace an extinguisher damaged or missing the building may not be conforming to the Fire Safety Order. This could result in an Fire Authority audit taking enforcement actions. The insurance policy may oblige you to comply with the laws that govern fire security. In the event of a significant delay in addressing the issue can be used by an insurance company to disqualify an insurance claim in the event that there is a fire. They could argue that you failed to maintain sufficient protection.

9. Management of Workload and capacity for Providers in Sutton Coldfield

The ability of a company to offer rapid response is directly correlated with its resource management. The ratio between the engineer and client of a company and the way they manage peak workloads are important concerns to inquire about. An organization with a large volume of work will discover that their technicians are running behind schedule in routine visits, but they're not equipped to effectively handle emergencies. During the tendering process it is important to ask the company how it would react to a situation which required replacement of several extinguishers on your facility. The response they provide will demonstrate the speed at which they can respond and in large numbers.

10. Monitoring of performance, reporting on it, and reviewing in Sutton Coldfield

Professional providers do not just make promises. They also measure the performance of their service. They must be able to monitor the time to respond for all types of calls. Furthermore, they must be prepared and willing to provide periodic performance reports, e.g. annual, which demonstrate their compliance to the SLAs stipulated in your contract. This transparency allows you to perform reviews based on data and holds them responsible for upholding high standards of fire safety compliance. See the recommended fire safety in Sutton Coldfield for blog recommendations.